Li.U Lab Model 3 Heat and Pressure Test

Succesful Heat And Pressure Test Of The Updated Lab Model V3 From The Three

GREC Sustainable Groups Joint Project at Linköping University

Background

Three

candidate groups at Linköping University built a GREC Lab Model

version 3. They did not perform any succesful test before completing their

term. After their project presentation the GREC was reassembled with tight

gaskets and made ready for empirical tests relating theory to reality.

The first revolving heat and pressure test of the Lab Model v3 was conducted

on July 17, 2023 by nilsinside AB in Motala, Sweden.

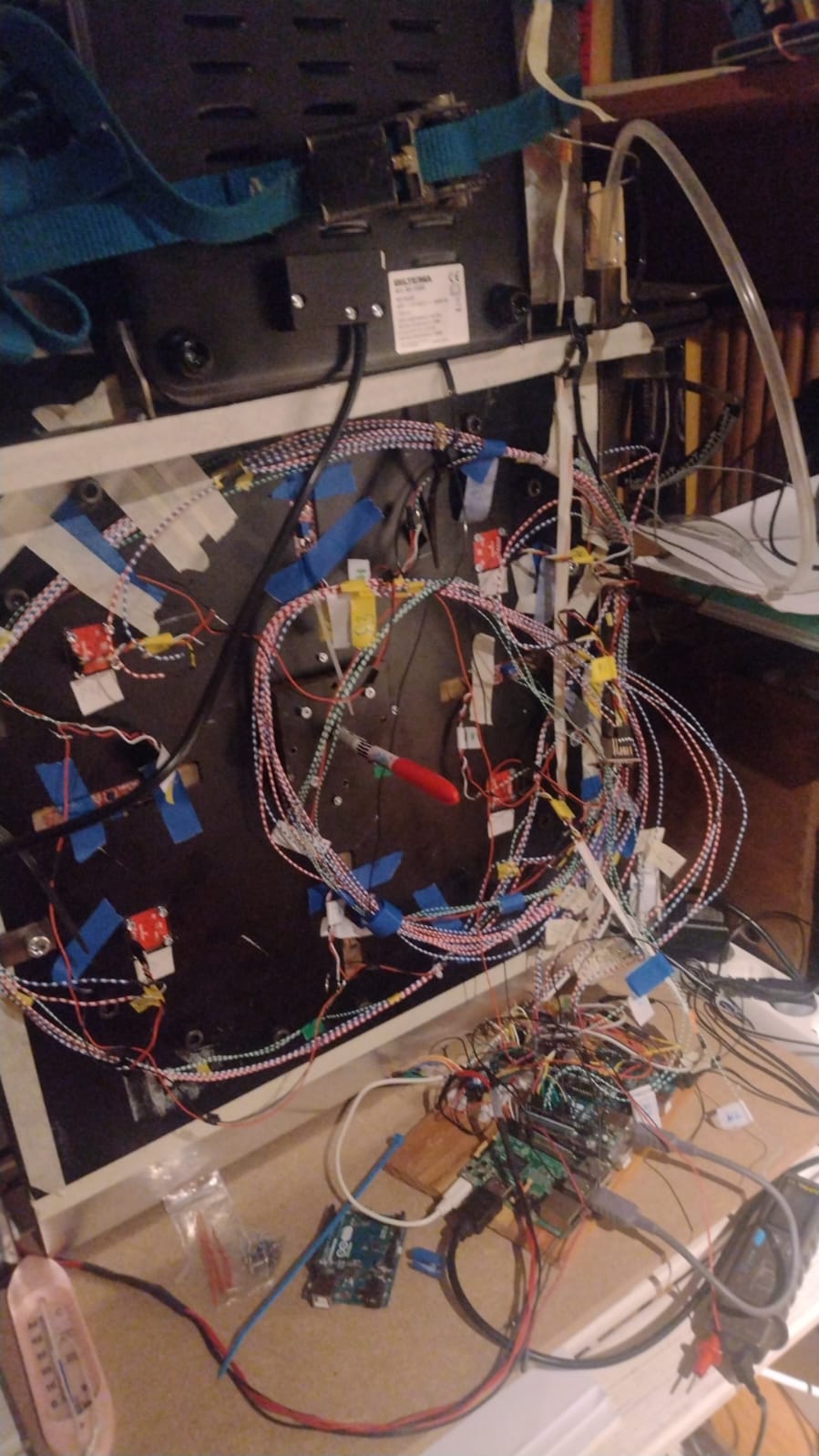

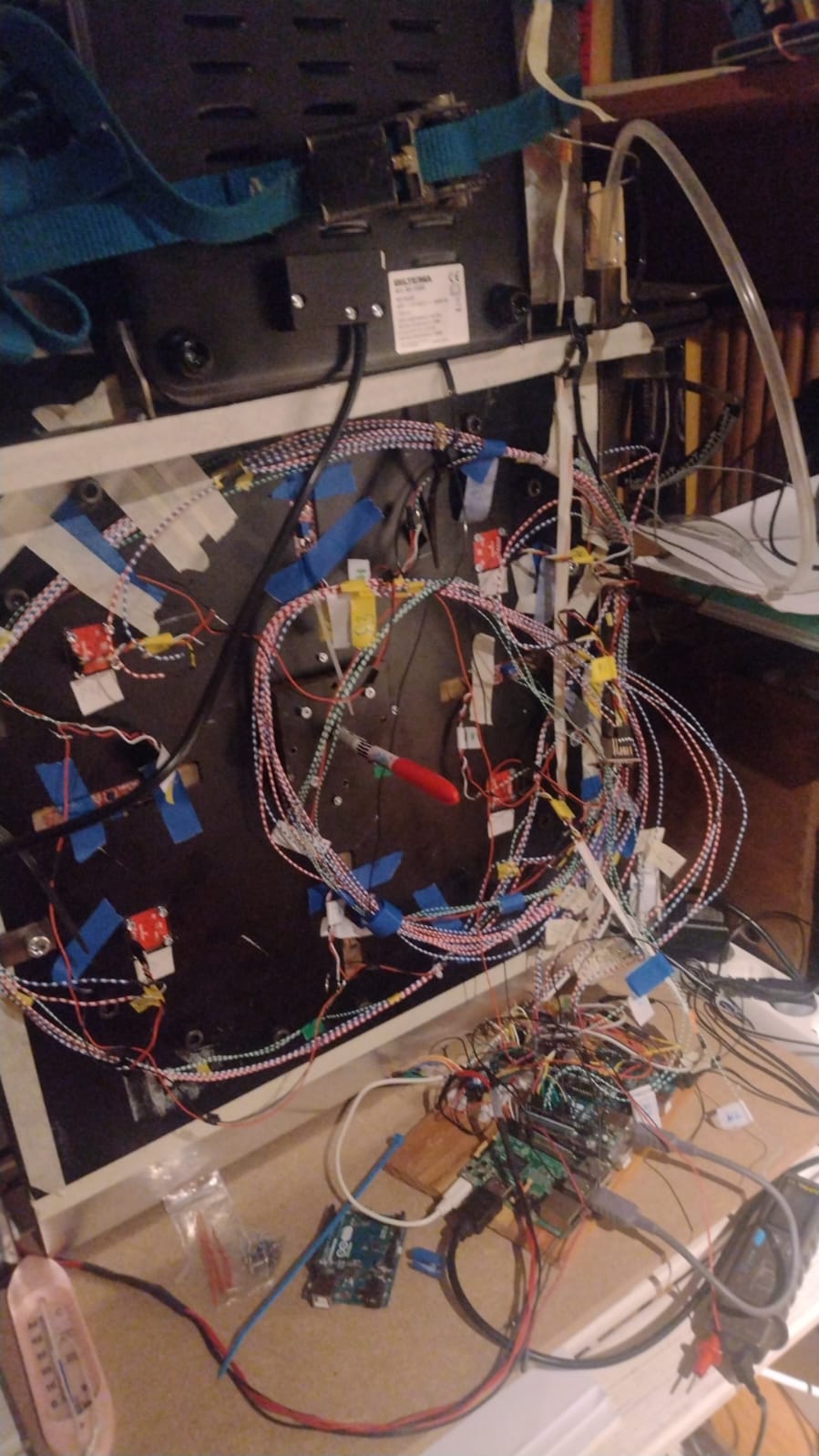

The Green Revolution Energy Converter (GREC) Lab Model V3 with

electrical heating strapped on top. A marker pen was used as a plug

The Green Revolution Energy Converter (GREC) Lab Model V3 with

electrical heating strapped on top. A marker pen was used as a plug

covering the hole for the moving boundary (piston, membrane or linear

generator) in the centre. Four red pressure sensors are in connection with

the total volume inside the Lab Model seen in positions

North-East (Column blue in diagram), South-East (red in diagram), South-West (yellow)

and North-West (green)

The test was conducted with the Mechatronics group software "Kombinerad_kod.ino"

resulting in a Work Generating Volume (WGV) revolution at about 1 Hz (60 RPM).

A higher revolution speed was expected but it seems like the sampling rate

interfered with the stepper motor control.

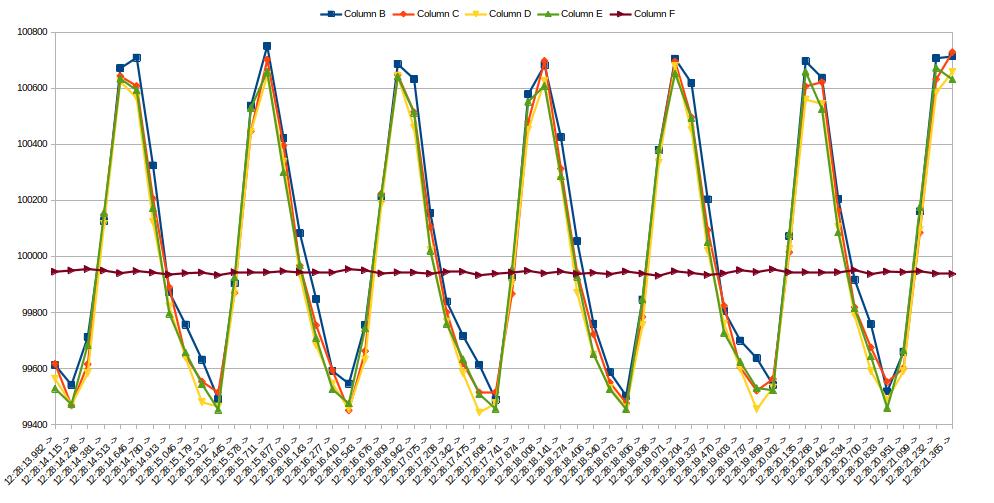

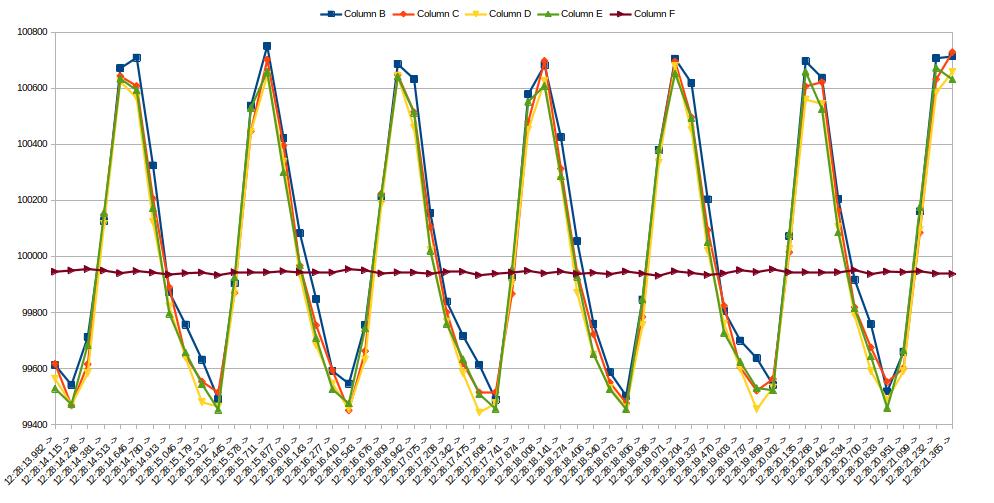

The software recorded 5 pressure sensors simultaneously. Four of the sensors

were connected to different positions of the LabModel total volume as

described in the image above and a fifth sensor recorded the ambient pressure

outside the closed system. A temperature difference ΔT of 55°C between the

two heat conducting sides with 20°C at the bottom and 75°C at the top. As in

the earlier test without heat gradient the four graphs follow each other so close

that they almost overlap.

The Green Revolution Energy Converter (GREC) Lab Model V3 heat and pressure test diagram showing overlapping graphs

The Green Revolution Energy Converter (GREC) Lab Model V3 heat and pressure test diagram showing overlapping graphs

Ambient temperature: 20°C (293K)

Cold side temperature: 20°C (293K)

Warm side temperature: 75°C (348K)

Temperature Gradient, ΔT = 55°C (55K)

Ambient pressure: 99 940 Pa

Maximum pressure in this test, P max: 100 751 Pa

Minimum pressure in this test, P min: 99 490 Pa

Pressure difference average in this test, ΔP = 1 249 Pa

Revolutios at approximately 1Hz (60RPM)

Notes:

• We suspect a small leak in the GREC. Hopefully the leak disappears when

we tightly cover the shaft passage areas.

• Sampling rate and revolving speed depends on I2C bus, software and the Arduino processor frequency.

As expected the graphs still overlaps. The pressure in the WGV as well as

in the "dead volume" is the same as in the total Lab Model V3 volume. It

might be that the graphs separate at faster revolving speed

The Technology

In thermodynamic terms the GREC is a closed system with a moving boundary

where the GREC converts heat energy to kinetic energy. The GREC heats and

cools its internal large sliced Work Generating Volume (WGV) efficiently,

rapidly and repetitively, resulting in internal pressure changes that

generate volume change work.

You may think of the GREC as a revolving Carnot heat engine controlled by

computer logics. Please find the theoretical presentation of

the GREC on this link:

GREC Theory Presentation

The GREC is a new technical solution to tackle climate change

and luckily there are technologist groups at Linköping University with the

challenge of transitioning to fossil-free energy systems. They have contributed

to several GREC climate-positive research projects over time.

Please feel free to call or email:

Contact information at nilsinside AB

Nils Karlberg nils@nilsinside.com, tel +33 608 53 15 93, theory & technical questions

Sophia Karlberg sophia@nilsinside.com , strategy & admin questions

The GREC Project