Verifying thermistor chain logging dynamic heat transfer

TEST: Verifying thermistor chain logging dynamic heat transfer.

TEST: Verifying thermistor chain logging dynamic heat transfer.

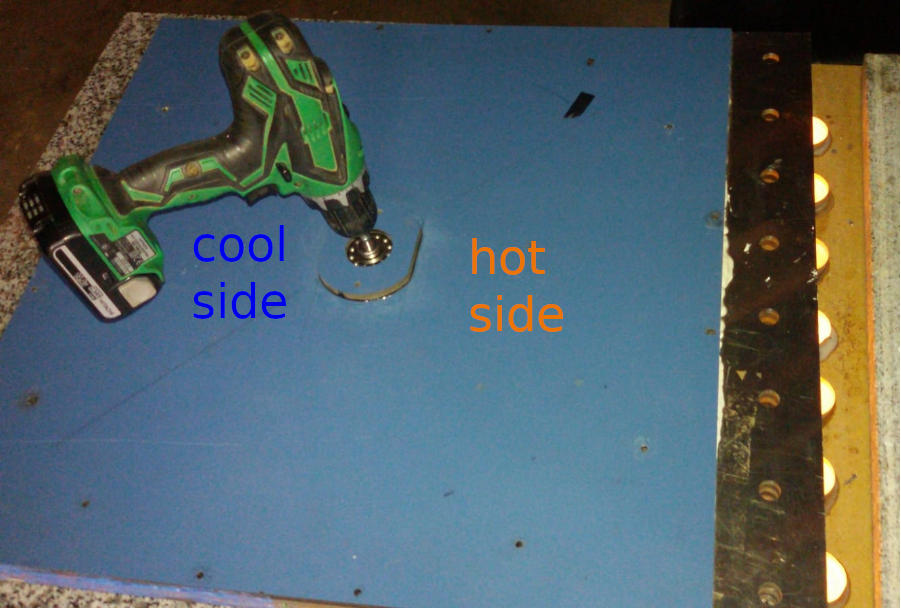

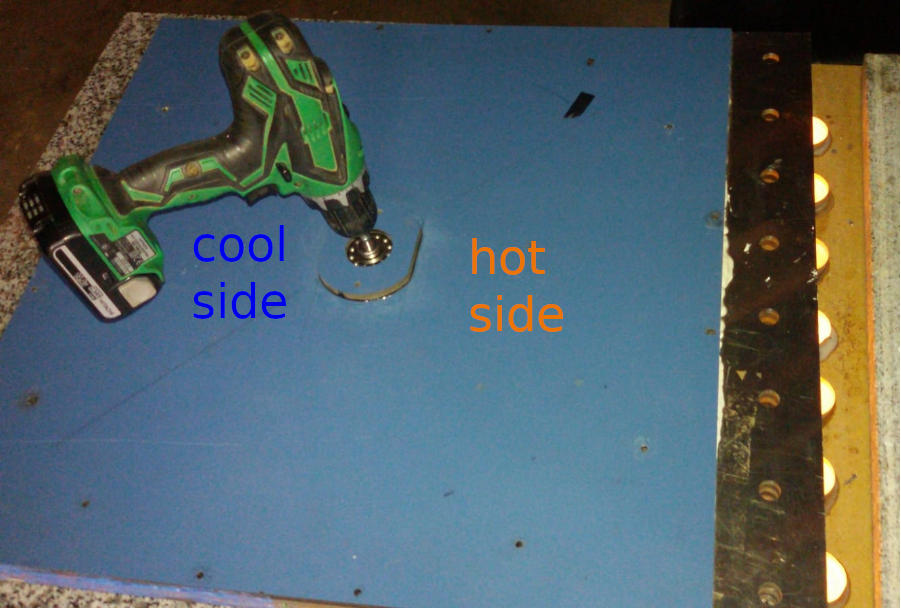

Still using candles as heat source but now with a closed "Green Revolution Energy

Converter" and now also rotating the internal two disk "Revolving Shutter"

with an electric screwdriver to verify the temperature sensors while logging

the dynamic heat transfer and to confirm our expectations. The "Green Revolution

Energy Converter" is not yet air tight so we are not monitoring the pressure.

This test is only verifying the logging capability of the heat transport:

- from the warm source (candles) to the Revolution Energy Converter

hotside conducting aluminium fin and the transport within the fin monitored

by its three pt500 heat sensors-

- heat leaving the hot side conducting fin from its surfaces into the gas

of the "Work Generating Volume" opening of the "Revolving Shutter". The

temperature of the gas is measured by the two pt500 sensors of the paired

insulating "nil" fin. So these two sensors are ment to measure the

temperature of the air/gas in the Work Generating Volume passing the

isolating nil fin between the hot and the cold conducting areas (not the

temperature of the material of the insulated "nil" fin, although there

is a relation.)-

- the heat is carried by the gas of the Work Generating Volume in the

turning Revolving Shutter over to the side where the cooler conducting

fins surfaces are absorbing the heat, from the gas into the conducting

cooler metal.-

- from the Green Revolution Energy Converter cool-side conducting fins into

the ambient air (cold sink).

Notes:

-I'm sure you noted that candles are not a very powerfull heat source,

but enough to verify the heat transfer.

-Unfortunaly the conducting fin surfaces are still covered with a coat

of paint that we used when tracing the Revolving Shutter friction. Heat

transfer from the conducting fin surface into the Work Generating Volume

of gas propably stays reduced until this coat is removed.

-The cool-side conducting fins only connects to the ambient air as a cold

sink. The area of the surface in contact with ambient air is limited and

unfortunately also still coated with gasket paste since our outdoor

experiments.